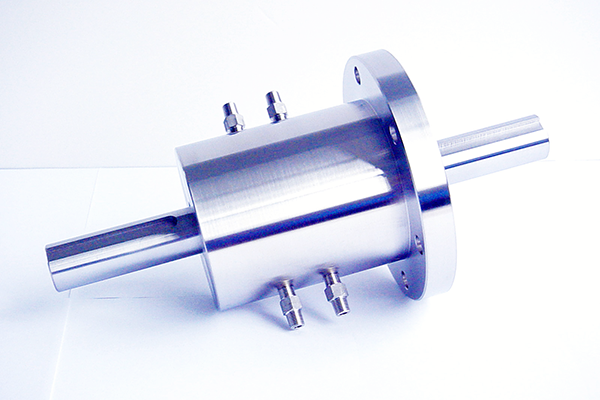

Ferrofluid Vacuum Rotary Feedthroughs from Moretec Inc.

PST GmbH provides service and distribution for vacuum rotary feedthroughs and magnetic fluid from Moretec Inc., Japan. With over 20 years of experience in manufacturing ferrofluid feedthroughs, Moretec products are widely deployed not only in Japan and Asia, but also throughout America and Europe. The magnetic feedthroughs operate reliably in: single-crystal silicon furnaces, sputtering systems, CVD equipment, FPD manufacturing equipment, and thin-film deposition systems. Send us your technical requirements - we will prepare a suitable quotation.

Request Your Custom Quote Now

As a European partner, we have been working closely with Moretec Co. for over 17 years. We maintain direct communication in product development and quality assurance. The Xiangxiang Manufacturing Base with its fully integrated production – from ferrofluid formulation to final assembly – guarantees consistently high quality for your vacuum applications.

Through direct communication with the development and manufacturing teams in Japan, we can implement customer-specific requirements efficiently. From thermal analysis and magnetic field calculations to selecting the optimal ferrofluid formulation – your technical specifications are precisely transferred into the feedthrough design. This partnership approach enables us to deliver suitable solutions even for demanding applications in semiconductor and coating technology.

Analysis Techniques

Precise Lifetime Calculation for Ferrofluid Seals

Moretec possesses world-leading technologies for calculating the lifespan of bearings and ferrofluid. Following the calculation, we show you specifically where optimization potential exists to further extend the lifetime of your vacuum rotary feedthroughs.

Thermal Analysis for Optimal Operating Conditions

Moretec analyzes how the viscosity of the magnetic fluid influences the seal temperature under your specific operating conditions. The results are validated experimentally to develop the optimal feedthrough design for your system.

Magnetic Field Analysis for Maximum Sealing Performance

Based on precise magnetic field analyses, the optimally matched ferrofluid with suitable magnets is selected for your application. This matching is critical for sealing performance in high vacuum.

Fluid Analysis and Flow Simulation

Through theoretical calculations of centrifugal force and ferrofluid flow motion, the ideal magnetic field for your specific process parameters is determined.

Manufacturing Techniques

Integrated Manufacturing in Japan

Moretec's ferrofluid feedthroughs are created through a fully integrated production process. From ferrofluid formulation through component manufacturing to final assembly and testing - all critical process steps are performed under one roof in Japan. This in-house production ensures continuous process control and avoids quality variations that can arise from outsourcing.

Precision Manufacturing

The heart of production consists of several state-of-the-art Japanese CNC lathes and machining centers. Complemented by automatic welding systems, ultrasonic cleaning systems, and specialized vacuum grease filling systems, Moretec achieves manufacturing tolerances in the micrometer range. This precision is crucial for the reliability of magnetic seals in high vacuum.

Over 15 Specialized Ferrofluid Formulations

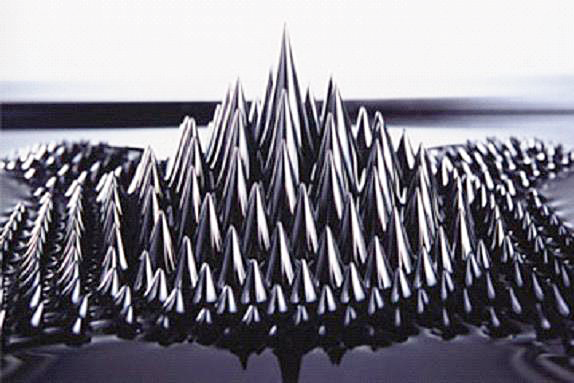

Not every application poses the same requirements. Therefore, Moretec has developed over 15 different ferrofluid types - tailored to different temperature ranges, pressures, and chemical environments. The magnetic fluid consists of Fe₃O₄ nanoparticles (approximately 10 nm in size), special surfactants, and a carrier liquid. This composition remains stable even under strong magnetic field gradients.

Dosing is performed with ultra-precision injectors that work with accuracy down to 1/1000 ml. Each vacuum rotary feedthrough receives exactly the required amount of ferrofluid - no more and no less. This precision is critical for consistent quality.

Multi-Stage Quality Control

Dimensional inspection occurs after each individual manufacturing step. Components that do not meet drawing specifications are immediately rejected or reworked. Final inspection additionally includes checking for surface scratches, burrs, and coating integrity.

Short Delivery Times

Despite extensive quality controls, Moretec delivers standard products within 45-60 days. This is made possible through optimized production planning.

Technical Comparison of Moretec Series

All Moretec Ferrofluid Rotary Feedthroughs at a Glance - Find the optimal series for your vacuum application:

| Series | Type | Diameter | Max. Speed | Max. Temperature | Vacuum Level | Main Application |

|---|---|---|---|---|---|---|

| SOLID SHAFT | ||||||

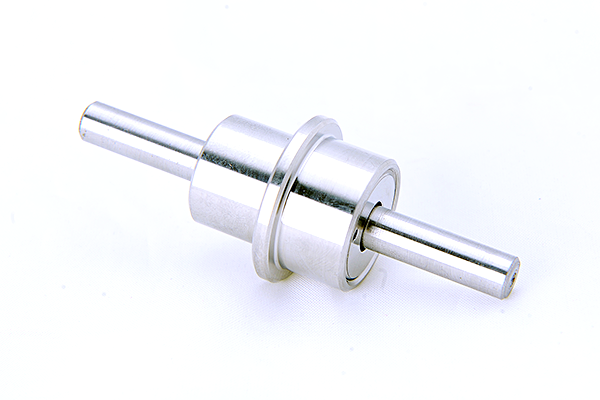

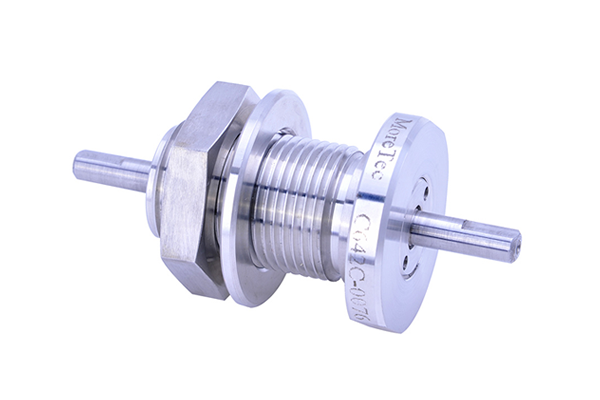

| SSB | Solid Shaft | 4-6 mm | 10,000 RPM | 80°C | UHV (10⁻⁸ Torr) | Precise UHV applications, compact |

| SMB | Solid Shaft | 6-12 mm | ~5,000 RPM | 80°C | HV/UHV | Medium torque, magnetically coupled |

| SNB | Solid Shaft | 6-10 mm | 18,200 RPM | 80°C | XHV (< 10⁻⁹ mbar) | Semiconductor manufacturing, highest purity |

| STB | Solid Shaft | 12 mm | 13,900 RPM | 200°C | UHV (10⁻⁸ Torr) | High-temperature processes |

| SFB | Solid Shaft | 10-25 mm | 6,000 RPM | 80-120°C | HV (10⁻⁷ Torr) | High speed, high torque (up to 1066 Kg·cm) |

| HOLLOW SHAFT | ||||||

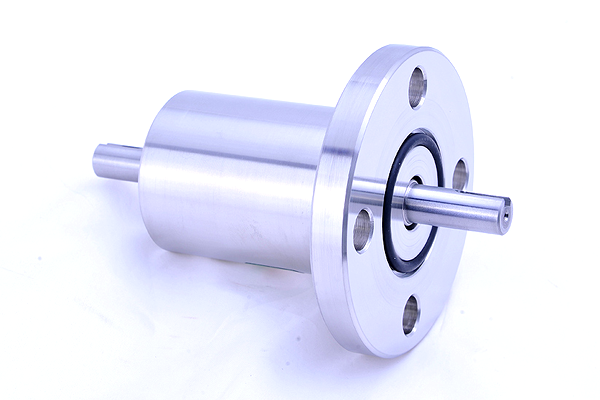

| HFB | Hollow Shaft | 10-75 mm | 5,800 RPM | 80-100°C | HV (10⁻⁶ Torr) | Cable routing, vacuum robotics |

| HTB | Hollow Shaft | 10-75 mm | ~3,000 RPM | 80-200°C | HV (10⁻⁶ Pa) | Hollow shaft + high temperature |

Notes:

Values are typical maximum values. Exact specifications depend on shaft diameter and configuration.

Vacuum specifications: UHV = Ultra-High Vacuum (10⁻⁷ to 10⁻⁹ mbar), XHV = Extreme High Vacuum (< 10⁻⁹ mbar), HV = High Vacuum (10⁻³ to 10⁻⁷ mbar).

For detailed data sheets and consultation:

Contact us or download technical documentation on our Downloads page.

Moretec Group

The Moretec Group was founded in 1998 in Tokyo, Japan, with the vision of revolutionizing sealing technology through the power of magnetic fluids. Over more than 25 years, the company has evolved into the world's leading manufacturer of ferrofluid vacuum seals, whose products are now deployed in semiconductor, coating, and vacuum systems worldwide.

Application Areas of Moretec Ferrofluid Vacuum Seals

Semiconductor Manufacturing - Single-Crystal Silicon Furnaces: Vacuum integrity in high-temperature processes - CVD Systems (Chemical Vapor Deposition): Leak-free environment for CVD reactors - PVD Equipment (Physical Vapor Deposition): Precise sealing for thin-film deposition - FPD Production (Flat Panel Display): Contamination-free processes for display manufacturing Photovoltaic Production - Solar Panel Manufacturing Equipment: Vacuum integrity during thin-film coating - High reliability under extreme process conditions Vacuum Technology - Vacuum Furnaces: High-temperature heat treatment and material synthesis - Vacuum Robotics: Sealed interfaces for moving components in cleanrooms